- Contactless removal of dirt without damaging the surface

- Cleaning without polluting the environment

- Cleaning during operation

- Contactless mold cleaning

- Cleaning vacuum chambers

- Turbine cleaning

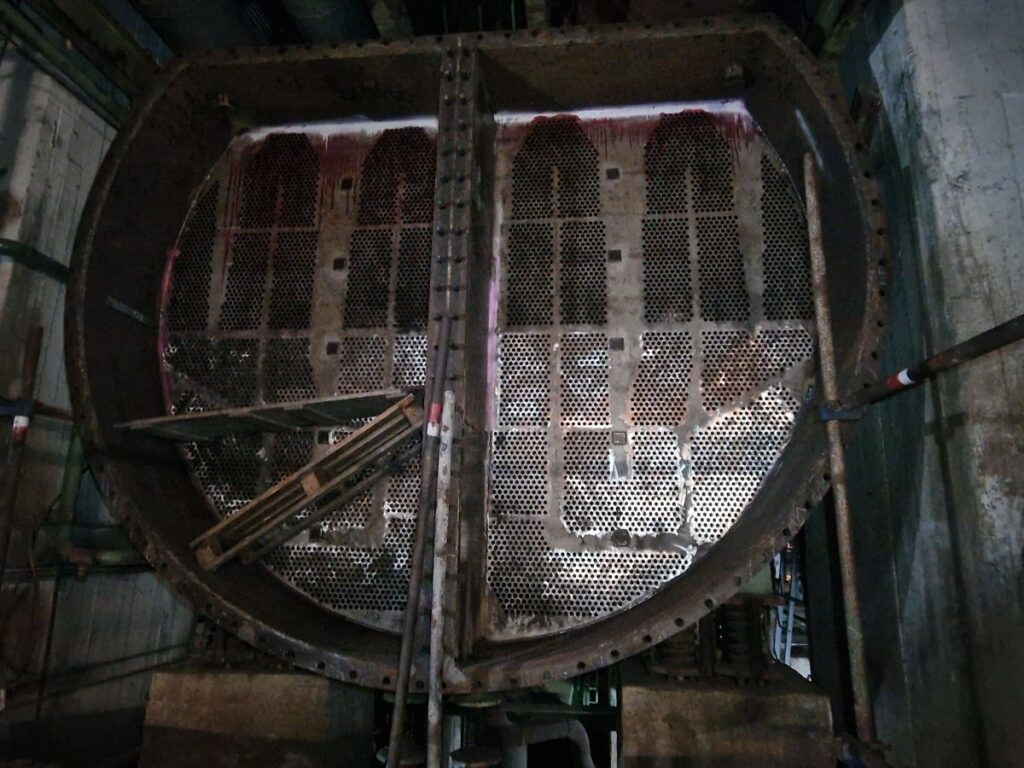

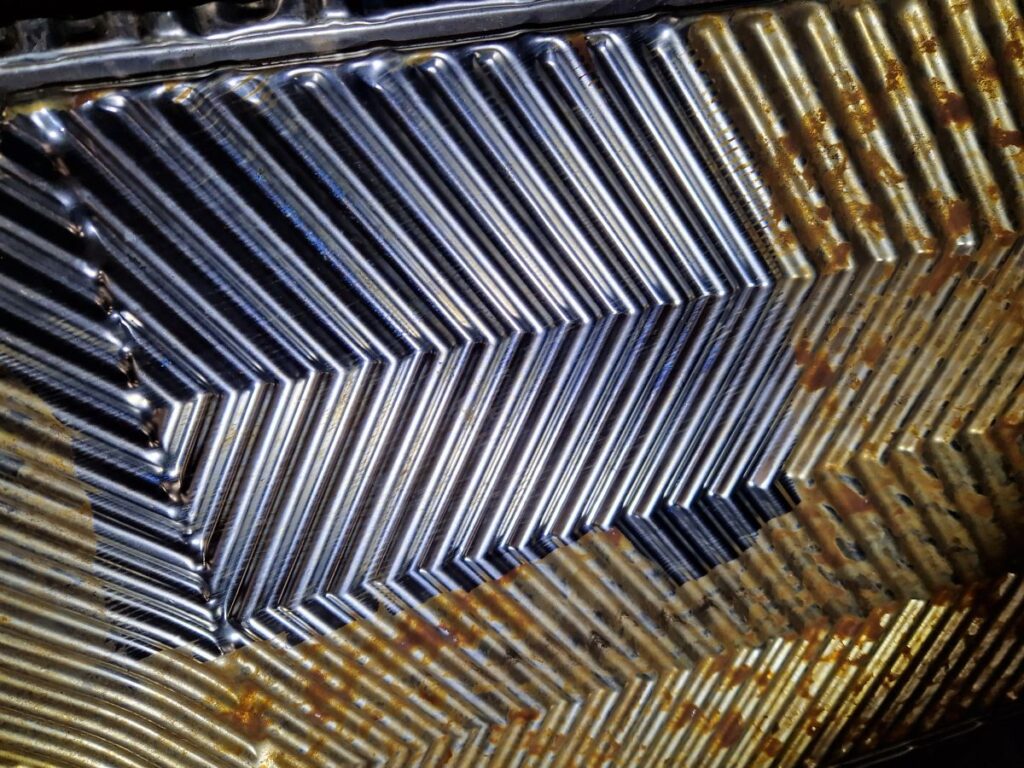

- Cleaning of heat exchangers

- Cleaning of production technologies

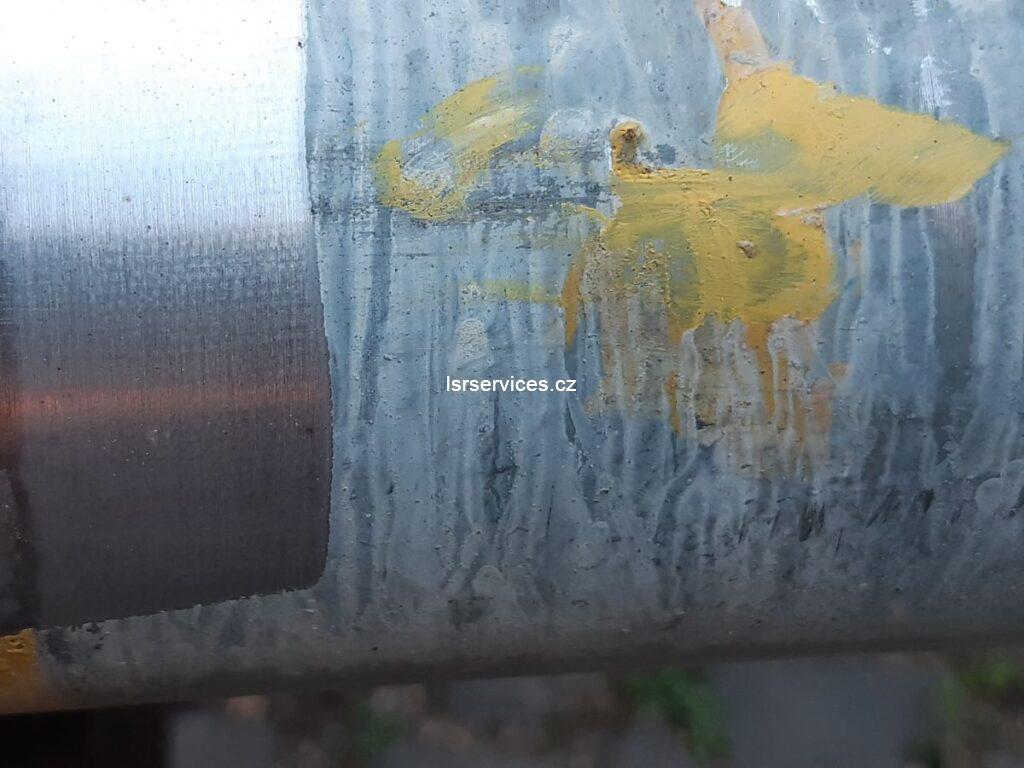

- Removal of rust and corrosion products

- Removing paints and adhesives

- Removal of lubricants and petroleum products

- Removal of organic and inorganic deposits

- Preparing material for applying new coatings

Realization

Vacuum chambers and clean rooms

Another application offered is laser cleaning of vacuum chambers. Using a laser, we are able to remove organic and inorganic deposits on the inner walls of the chambers. Thanks to the removal of dust particles and porous impurities with a large specific surface, the required vacuum is established more quickly, evaporation and subsequent contamination of industrial processes do not occur. Another similar application is laser cleaning of clean rooms. Thanks to it, it is possible to significantly reduce the amount of dust particles. Our workers have many years of experience in operating clean rooms according to GMP and ISO classification , the modified pulse laser minimizes the emission of dust particles and the risk of microbial contamination.

Tailor-made processes for clients

In addition to the above-mentioned applications, we deal with a tailor-made optimized process. We often supplement laser cleaning with chemical cleaning , which combines the advantages of these methods. In this way, impurities of both organic and inorganic origin can be removed in a virtually contactless manner with maximum care for the underlying material.

Cleaning of glass tubes

One specific example is the cleaning of the inner walls of quartz glass tubes , which occurs at very high temperatures in a reducing atmosphere. The impurities containing the organic phase, lubricant residues, carbon and a significant amount of chromium and nickel carbide and other metal complexes are mechanically resistant, chemically inert and even a temperature of around 2000°C does not affect their structure. The previous mechanical cleaning was associated with damage to the inner surface of the tubes and subsequent higher deposition of impurities. Using a pulsed laser and subsequent multi-stage chemical rinsing, we clean the inner walls of the tubes without any damage and wear of the surface.

Cleaning without disturbing the surface

Another example is the laser cleaning of surfaces in a production line for applying hot melt adhesives to glass sheets. The laser can be used to clean surfaces without their lengthy and expensive dismantling and long-term stoppage of the production process. Compared to chemical cleaning, laser cleaning is significantly faster , there is no need to dismantle bearings. The fine surface structuring of the application roller is not disturbed .