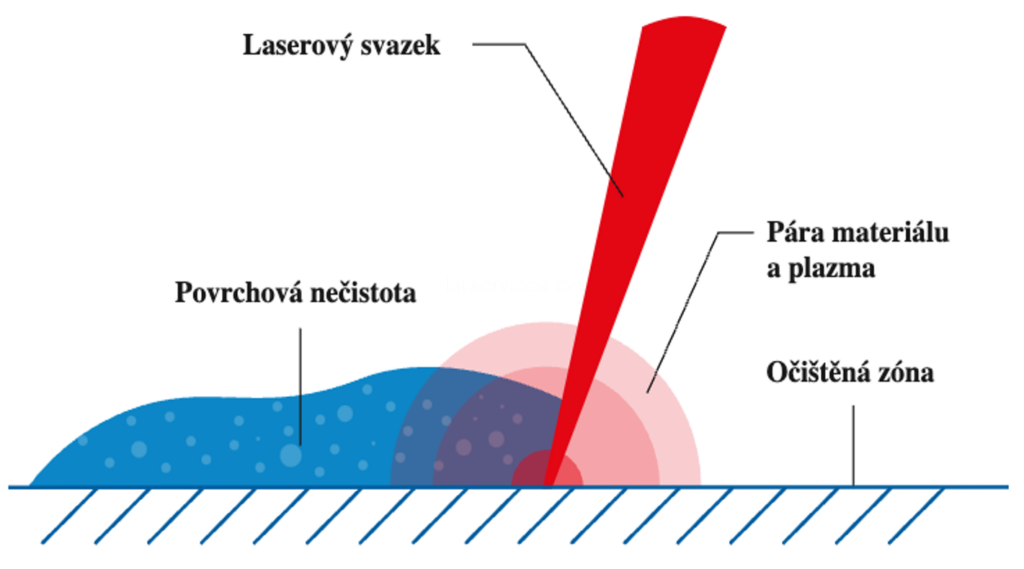

Principle of laser cleaning

Laser cleaning is based on so-called laser ablation. It involves the interaction of the material being cleaned with very strong light radiation. When the radiation hits the dirt, it is absorbed and subsequently the covalent chemical bonds in the molecules are broken and they disintegrate. In this way, it is possible to very effectively remove, for example, rust, old coatings, mineral oils and other grease, soot, metal complexes , etc. The underlying material itself does not absorb the beam, but reflects it. Therefore, there is no transfer of energy and no damage to its surface.

The interaction of a laser beam with a contaminated material is accompanied by a number of physical processes, primarily sublimation, melting, evaporation, shock waves, acoustic effects, etc. These phenomena can be used very effectively in practice to remove various contaminants from various materials and according to various requirements. By appropriately setting the individual parameters of a pulsed laser , such as pulse energy, its length, frequency, light beam trajectory, etc., one can choose, for example, between very intensive rough removal of contaminants, or, conversely, gentle cleaning, when, for example, it is desirable to preserve a certain patina on historical objects.

Benefits of laser cleaning

- This is a non-abrasive, non-contact cleaning process - with appropriate laser parameters, the underlying material is not disturbed in any way. Even with repeated cleaning, the shapes of the molds do not change or the fine contours of the surface of historical objects are not disturbed.

- During laser cleaning, impurities are transformed into a gaseous phase. There is practically no pollution of the surroundings , no secondary waste is generated, and it can be operated indoors, during normal operation or in public.

- When the laser parameters are set appropriately , there is no thermal or mechanical stress on the underlying material and thus no changes in its shape and fine surface structure.

- The laser can be used to clean surfaces of various metals, stone, concrete or wood .

- Laser cleaning easily cleans complex surfaces such as ribbing, filter grilles, expanded metal, and materials with different structures and compositions.

- Modern pulsed lasers are highly efficient, a large part of the energy is used to degrade the impurities themselves, making cleaning energy-efficient . Since no secondary waste is generated, laser cleaning is environmentally friendly .